Bowman Expands Sales Team

March, 2021 – Bowman has appointed Ryan Ahrens as sales and support engineer for the high-activity region that includes southern California, also Arizona, Oregon and Washington.

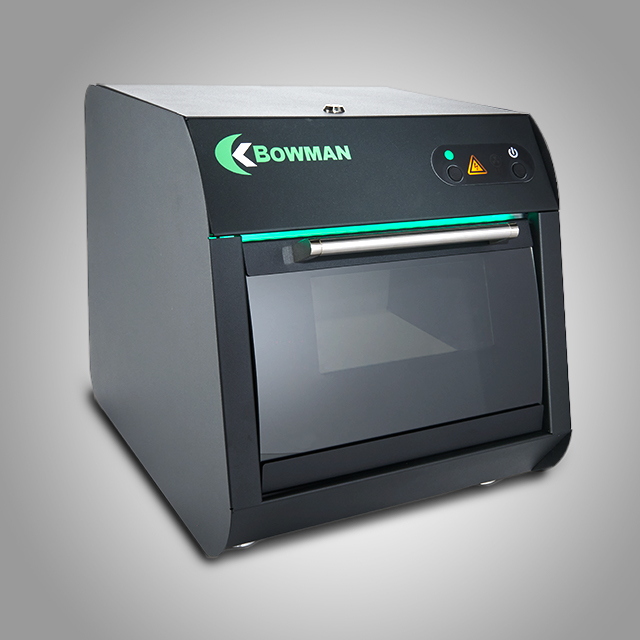

Mr. Ahrens was previously a technical sales engineer, based in Dallas, with Keyence, a global supplier of sensors, measuring instruments, and machine vision systems. As a sales and support engineer, he will work with Bowman customers in the PCB manufacturing and metal finishing industries, providing consultation, installation and support for all seven models of Bowman XRF plating thickness measurement systems.

Mr. Ahrens holds a B.S. in chemical engineering and an MBA from the University of Alabama; he is a member of AIChE*. His base is Santa Ana, California.

* American Institute of Chemical Engineers

Made in the USA

Made in the USA