Coating thickness measurement is a requirement for manufacturers who plate coatings onto metal parts, as instruments ensure quality, precise specifications and economize spending.

Bowman coating thickness measurement instruments have proprietary detection technology and advanced software which allows systems to also determine elements present in the sample. Our XRF instruments simultaneously measure up to five coating layers, all of which can be alloys, and can measure HEAs (high entropy coatings) as well.

A micro focus video camera, aligned with the x-ray optics axis, selects the area on the sample to be measured. An elevator controlled by a focus laser accommodates measurement samples of varying heights.

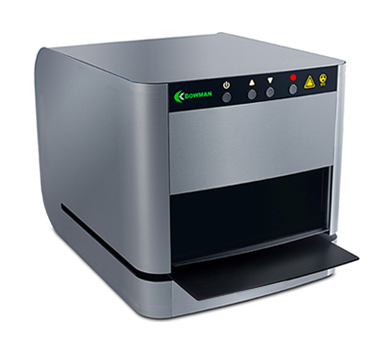

The Bowman XRF coating measurement system meets industry’s most stringent requirements for precision, reliability and ease of use. A compact, ergonomic design makes analysis convenient for every application—at a price guaranteed to produce a fast ROI.

What do you want to achieve?

Greater accuracy? Faster throughput? More flexibility in sample size – or output?

Let’s talk.Configurations for Every Measurement Need

- G Series transition metals analysis for the jewelry industry

- B Series for small electroplated samples

- P Series “multi-tasker” for electronics, general finishing, precious metals

- L Series for large electroplated samples

- K Series 12” x 12” measurable parts area

- O Series large thin film analyzer

- M Series small thin film analyzer with µ-spot poly capillary optics

- W Series for measuring the smallest features in microelectronics

- A Series for precise measurement of semiconductors & microelectronics

- Fast non-destructive analysis within seconds

- Simultaneous composition analysis of up to 30 elements

- Measure up to five coating layers simultaneously, all of which can be alloys

- Fundamental Parameters (FP)-driven standard-less thickness and composition analysis

- Easy setup and operation-one USB cable connection

- Simple front panel controls

- Small footprint

- Lightweight

- Designed to maximize flexibility and minimize user errors

- Advanced Archer software

- Intuitive icon-driven graphical interface

- Powerful qualitative analysis

- Standard library with automatic recertification reminder

- Customizable shortcut keys for quick analysis

- Flexible data display and output

- Powerful report generator

- Close-coupled geometric design for increased power efficiency and precision

- Field-proven, solid-state detector provides greater resolution, stability and sensitivity

- Fast warm-up time and longer x-ray tube filament life

- L line Thin Film analysis for Ag, Sn

- Multiple primary filters and collimators for versatility

- Variable focal depths for complex sample shapes and thicker layer analysis

- Modular component design for easy maintenance

Four Sample Stage Options

Standard

Fixed Base

Extended Programmable

XY Base

Motorized/programmable

XY Base

Maximum Travel Extended

XY Base

Made in the USA

Made in the USA