Bowman XRF instruments use X-ray fluorescence technology to determine the thickness and composition of plating deposits with exceptional accuracy. Measurement is performed by exposing a precisely defined area of the test specimen to x-ray energy. This causes X-ray emission (fluorescence) from both coating and substrate, which is detected with a high precision energy-dispersive detector.

Energy resolution, detection efficiency, and robustness are three factors relative to detectors. Energy resolution is the ability to separate two photons having a small energy difference. Detection efficiency refers to the efficiency of x-ray documentation. All Bowman XRF systems use the advanced solid state detector technology of a Silicon Drift Detector.

Software

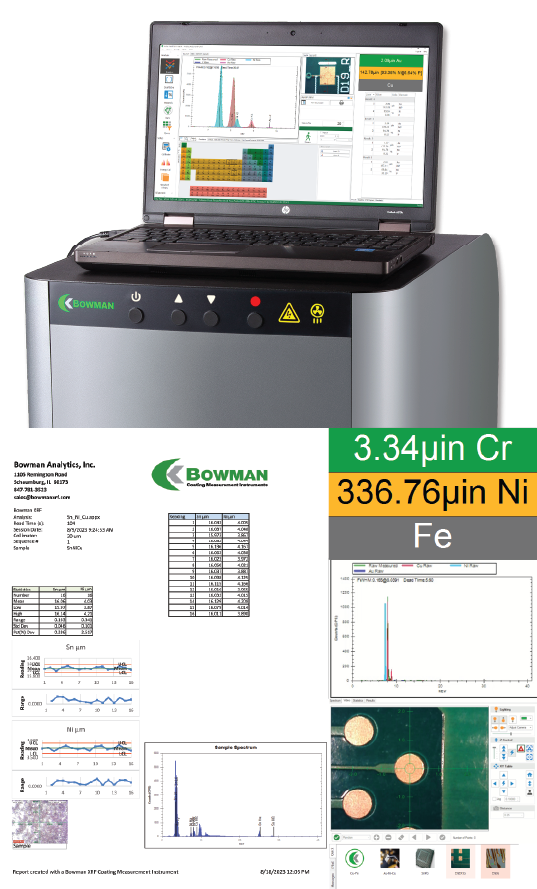

Once XRF data is generated from a sample, software converts X-ray intensity to thickness or composition. The software has two components: spectrum processing and quantitative analysis.

- Spectrum processing uses energy calibration, spectrum stabilizing, peak identification, dead-time correction, sum peak correction, escape peak correction, overlap correction, and background removal to extract X-ray intensities from a spectrum.

- Quantitative analysis calculates thickness and composition from XRF intensities. Due to the matrix effect, the relationship between intensities and thickness/composition is complex. The matrix effect is an inter-element or inter-layer effect. The fluorescence X-rays from one element could be absorbed – or enhanced – by other elements in the sample. Therefore, the relationship of composition/thickness to fluorescence X-ray intensities of one element is dependent on other elements that exist in the material.

Performing Quantitative Analysis

There are two ways to perform quantitative analysis. Empirical methods, such as interference coefficients, alpha coefficients, and others, approximate the matrix effects with a polynomial function. These methods requires that multiple standards within a narrow range be used in a calibration. The advantage is that these methods do not require sophisticated calculation, and are easy to understand and implement.

The FP method corrects for matrix effect through a theoretical calculation. The calculation is based on laws of physics and fundamental physics parameters. In theory, FP does not require calibrations and functions over an extended range. A calibration is still needed to minimize the errors in physical parameters and system uncertainties. The algorithm for FP was published in the 1970s, and differences between various FP software systems are not significant. An FP cal is more complicated than an empirical cal and requires greater computing power.

Bowman employs both Emp and FP methods

on its XRF software platform.

The Role of XRF Instruments in Metal Finishing / Final Finishing

XRF coating thickness measurement is a necessity for the $10 billion metal finishing industry. It is also the technology tool that allows contract platers, whose margins are always under pressure, to deliver high quality coatings at lowest cost, knowing they are avoiding the risk of producing below spec, and the cost of wasting valuable material.

Bowman XRF analyzers provide non-contact coating thickness measurement for every element, and alloy, from aluminum to uranium. Our instruments are the industry standard for very thin multi-layer alloy coatings on small parts and on complex shapes.

Elemental Analysis

Where layers of pure metals or alloys are used to enhance product features, it is important to precisely determine both coating thickness, and the elements in the sample.

Applications for elemental analysis

- Materials analysis of coatings and alloys

- Goods in inspection

- Manufacturing process control

- Trace analysis of contaminants

- Materials research & development

- Plating composition and thickness analysis for electronic components and connectors

- Analysis of PCB finishes, e.g. gold and palladium alloy coatings of ≤ 0.1μm, and nickel coatings

- Analysis of imported gold (and other PMs), jewelry and watches

Bowman XRF systems integrate coating thickness measurement and elemental analysis in one package, streamlining the quality control process.

Solution Analysis

The management of plating bath components, including both primary components and trace components and additives, is critical to quality and cost control.

Bowman XRF technology provides a high-precision, non-destructive, fast and user friendly way to analyze the metallic content of plating solutions.

Made in the USA

Made in the USA