May, 2019 – Two experts in PCB fabrication, each the owner of a company that represents top manufacturers of PCB chemistry, tools and equipment, are the latest additions to the Bowman Partner Network, a global alliance of distributors and rep firms.

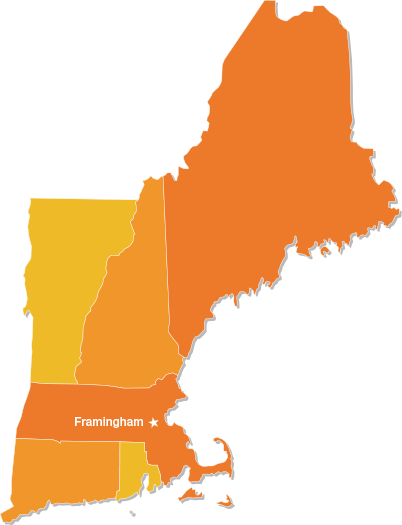

Richard Hegg and his company, ROH Sales, is based in Lake Bluff, Illinois, and will manage sales and service for Bowman XRF systems in Illinois and Wisconsin. “The Bowman line is clearly the right product at the right time, thanks in part to IPC specification 4552-A,” says Hegg. “ENIG, and what’s required to do it efficiently, is always part of the conversation,” he adds, “and there is strong interest in ENEPIG as well with IPC 4556.

“Bowman is strong among board shops, because it truly listens to customers,” he adds, “and it’s building its brand fast among OEMs. People also recognize they have a great service organization, which is a huge advantage.”

Scott Griggs, and his company, International Process Technologies, have become the Bowman Partner company for Minnesota. Based in Minneapolis, “IPT” focuses on both the PCB and metal finishing industries. In regard to the former, “4552 and the ENEPIG specs have tightened,” says Griggs, “and made accuracy more important than ever. This bodes well for Bowman equipment, because it tells you immediately if you’re meeting those specs.

“As a chemical vendor, I’m always asking how the plating bath is working. I’ve also seen the chaos that ensues when foreign-made XRF equipment goes down and the customer is unable to get support – or even a return phone call – for weeks.”

Made in the USA

Made in the USA