Control a Complex Process with Confidence

Platers need to control a complex process with multiple variables to achieve plated parts that comply with all the chemical, physical, and visual properties defined in the parts' specifications. One of the most critical variables is the ever-changing concentration of the metal in solution, which depletes over time as dissolved ions deposit onto the part. The concentration of these ions in solution is important to monitor, as it directly affects the plating rate and the deposit composition.

Traditional methods of measuring plating analyte concentration include atomic absorption (AA) and inductively coupled plasma (ICP). These involve expensive instruments and specialized lab personnel. Also, both require dilution of the plating bath to low concentrations for analysis, again requiring skilled lab personnel to minimize errors. Titration is an option for some metal solutions, but it's a time-consuming technique with its own limitations in accuracy and applications. Due to these factors, many platers depend on outside labs for analytical testing. This can be costly and create delays based on a lab's workload and lead times.

XRF is a fast, easy, and accurate method for analyzing metals in plating solutions directly and in-house, with existing production personnel. Simply pull a sample from the plating tank, fill a provided Bowman solution cup with the liquid, place a Mylar film and lid on top, and place the cup in the XRF chamber just like any other sample. Results are obtained in 60 seconds or less. Metal concentrations can be measured down to approximately 100ppm and often lower.

Read about the performance for single or multi-element plating bath analysis below.

Accessories

All 9 XRF systems in the Bowman suite measure the concentration of metals in solutions. Bowman software allows owners to create new applications as needed. All that is needed to perform solution analysis is Bowman's solution cup kit, pictured to the right.

Presenting a consistent volume of liquid, and collecting a strong signal from the sample are paramount for achieving accurate results. These specially designed cups satisfy both requirements. A molybdenum plate forms the bottom of the cup, reducing background scattering from the light matrix properties of the solution and providing a clean spectrum for accurate processing. An overflow reservoir collects any excess liquid pushed out from placing the Mylar film over the liquid and ensures that the analysis reservoir is always full. Only a few drops of solution are required. The chemically resistant Teflon cup and Mylar film ensures that even the most aggressive plating solutions are safely contained.

Bowman XRF systems measure all 3 critical metrics that are critical for consistent, high quality plating: plating solution concentration, deposit thickness and sample composition. Bowman is the leader in XRF plating analysis instruments, as well as auxiliary products such as reference standards and the solution analysis kits demonstrated in this short video.

Bowman XRF systems measure all 3 critical metrics that are critical for consistent, high quality plating: plating solution concentration, deposit thickness and sample composition. Bowman is the leader in XRF plating analysis instruments, as well as auxiliary products such as reference standards and the solution analysis kits demonstrated in this short video.

Bowman solution cup with Mylar film. Simply pipette a few drops into the central reservoir, place a Mylar film over the liquid, and snap the top on. An overflow reservoir and chemical-resistant cup eliminate any concerns over sample spillage or damage to the XRF instrument.

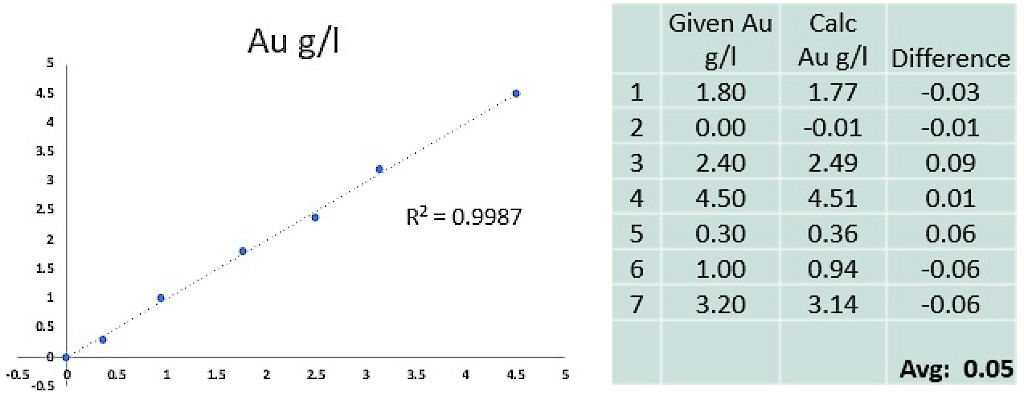

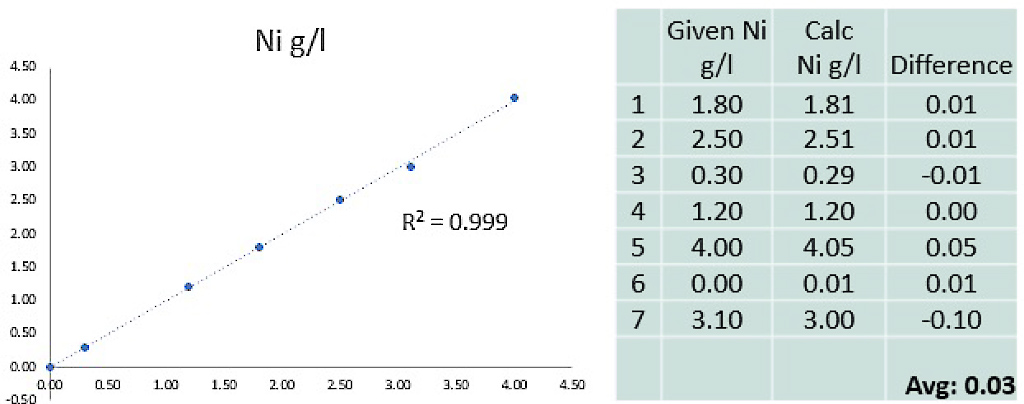

Single Element Solution Analysis: Typical Performance Data

New Multi-Element Solution Analysis

The new multi-element solution analysis software developed by Bowman allows users to measure more than one element or analyte at the same time, taking into account the matrix effect and impurities in the bath. The matrix effect refers to the influence or interference by other components present in the solution being analyzed. The plating bath solution is not a constant. Once the proper components are added, the plating process itself changes the composition of the solution, the level of contamination, and in some cases, the acidity.

Read the Application Bulletin #16 – Multi-Element Solution Analysis to learn more about this technique as well as the results of on two different studies.

Conclusion

Bowman XRF systems are versatile analytical tools for measuring plating bath solution concentration, along with plating deposit thickness and sample composition. The reduced costs of time, personnel, and instrumentation required by other methods make Bowman XRF an excellent alternative. Call our Technical Team for more information.

Need Help? LET’S TALK

Made in the USA

Made in the USA